Hot New Products Vicryl Polyglactin 910 - Implant Abutment – Foosin

Hot New Products Vicryl Polyglactin 910 - Implant Abutment – Foosin Detail:

Implant abutment is the middle part connecting the implant and the upper crown. It is the part where the implant is exposed to the mucosa. Its function is to provide support, retention and stability for the crown of the superstructure. The abutment obtains the retention, torsion resistance and positioning ability through the inner abutment link or the outer abutment link structure. It is one important part in the Implant System.

Abutment is an auxiliary device of implant in dental restoration. After the implant is implanted surgically, the abutment will also be attached to the implant for a long time through surgery. The abutment extends to the outside of the gum to form a penetrating component for fixing dentures and other orthotics (restorations).

There are many kinds of abutments with complex classification. Among them, titanium alloy abutment is widely used. Titanium is a good material with biocompatibility, durability and strength. After decades of clinical verification, its implantation success rate is relatively high. At the same time, it has good wear resistance and corrosion resistance, and has little impact on the oral cavity.

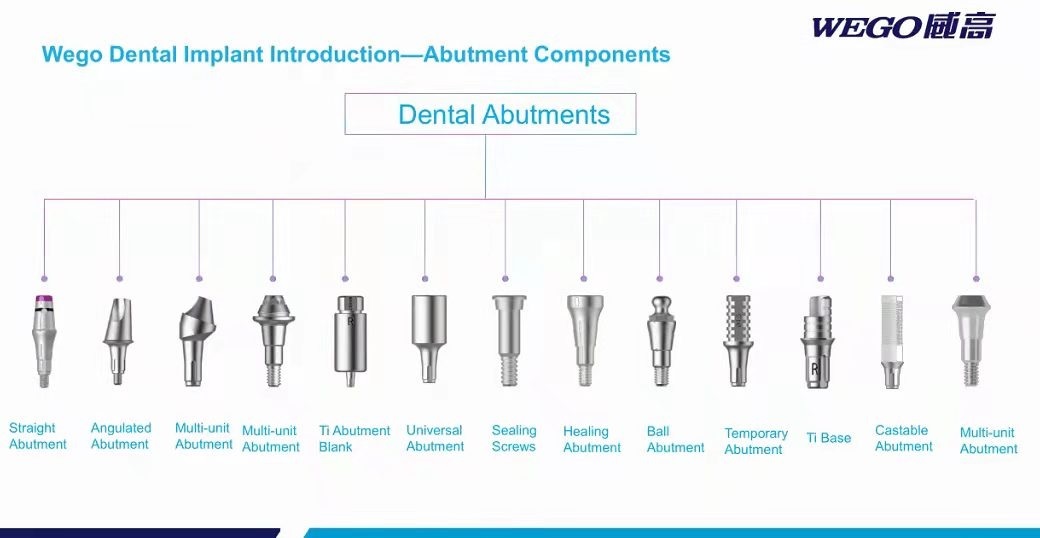

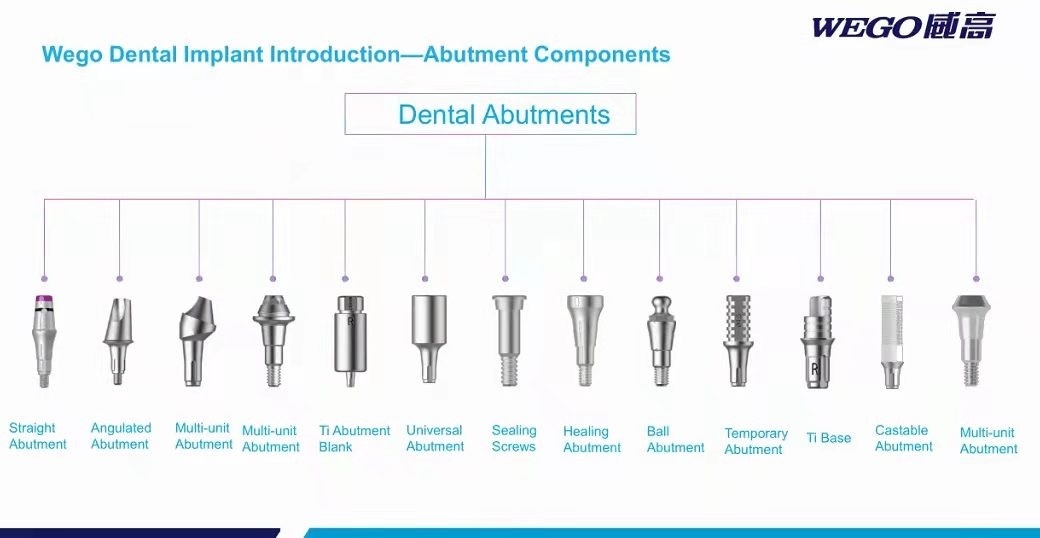

At present, the abutment can be classified according to the connection mode with the implant, the connection mode with the superstructure, the composition structure of the abutment, the manufacturing mode, purpose and materials of the abutment.

Abutment is widely used in clinic, which is divided into finished abutment and personalized abutment.

The finished abutment, also known as the preformed abutment, is directly processed and mass produced by the implant company. There are many kinds of finished abutments, which can be divided into temporary abutments, straight abutments, castable abutments, ball abutments, composite abutments, etc. Many studies have shown that the finished abutment has excellent mechanical properties. Because the finished abutment is designed and processed by the planting system manufacturer, the finished abutment has a good matching degree at the implant abutment connection interface, which can prevent micro leakage and enhance the fracture strength of the abutment.

Personalized abutment, also known as customized abutment, refers to the abutment made by grinding, casting or computer-aided design / computer-aided manufacturing (CAD / CAM) technology according to the implant implantation site, the three-dimensional position of missing tooth space and the shape of gingival cuff to be restored. This need support from the local measure-design-production center with after sale system introduced together.

Wego owns the most advanced machines for R&D with rich experiences in the past years, all the dental implant system still in the improvement and optimizing.

Product detail pictures:

Related Product Guide:

We have now probably the most innovative production equipment, experienced and qualified engineers and workers, regarded high quality control systems and also a friendly expert income team pre/after-sales support for Hot New Products Vicryl Polyglactin 910 - Implant Abutment – Foosin , The product will supply to all over the world, such as: Afghanistan, Iraq, Vietnam, We have a good reputation for stable quality products, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with customers both at home and abroad. We expect sincere cooperation and common development!

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!